The tool and mould making industry is facing new challenges. At a time when sustainability and efficiency are becoming increasingly important, established industries must also break new ground in order to meet these demands. Toolcraft AG is increasingly focussing on additive manufacturing in order to produce tools that are not only more innovative but also more sustainable.

Traditional production of moulds and tools: an overview

Traditional toolmaking is an elaborate process that has been practised for centuries. Historically, the manufacture of tools began with the forging, casting and machining of metal. In the traditional method, tools are often produced by milling, turning and grinding from solid block materials. However, this can lead to considerable material loss and is often time-consuming. The production of moulds for injection moulding or die casting is also based on traditional techniques such as investment casting or the machining of steel blocks, which entails considerable costs and high resource expenditure.

Additive manufacturing: New dimensions in tool manufacturing

Additive manufacturing is revolutionising this traditional approach by producing workpieces layer by layer. A leading process in this area is Laser Powder Bed Fusion (L-PBF). In this process, the workpiece is built up layer by layer by melting the material to be processed in powder form using a laser. The L-PBF process enables the production of highly complex components that are both lightweight and robust. The L-PBF process shows its strengths particularly in the areas of lightweight construction, functional integration and complex structures. ‘Additive manufacturing opens up completely new dimensions for us,’ says Uwe Schulmeister, Head of Additive Manufacturing at Toolcraft AG. ‘With this technology, we can not only optimise existing tools, but also produce new tools in a more efficient and environmentally friendly way.’

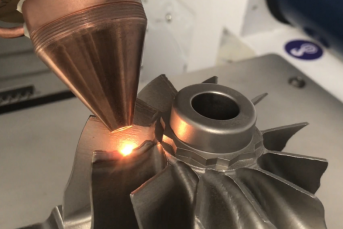

Laser Metal Deposition (LMD): efficiency through sustainability

Another forward-looking process is laser metal deposition (LMD). This additive process offers enormous advantages, particularly in toolmaking. Instead of having to completely remake defective or worn tools, they can be repaired and even optimised through precise material deposition. This not only saves time and costs, but also significantly reduces the amount of material used. Typical applications for LMD include the repair of turbine blades, shafts or tools. LMD also enables the application of functional coatings, such as wear and corrosion protection. ‘The combination of repair, coating and hybrid construction methods makes the LMD process a real all-rounder,’ emphasises Schulmeister.